About

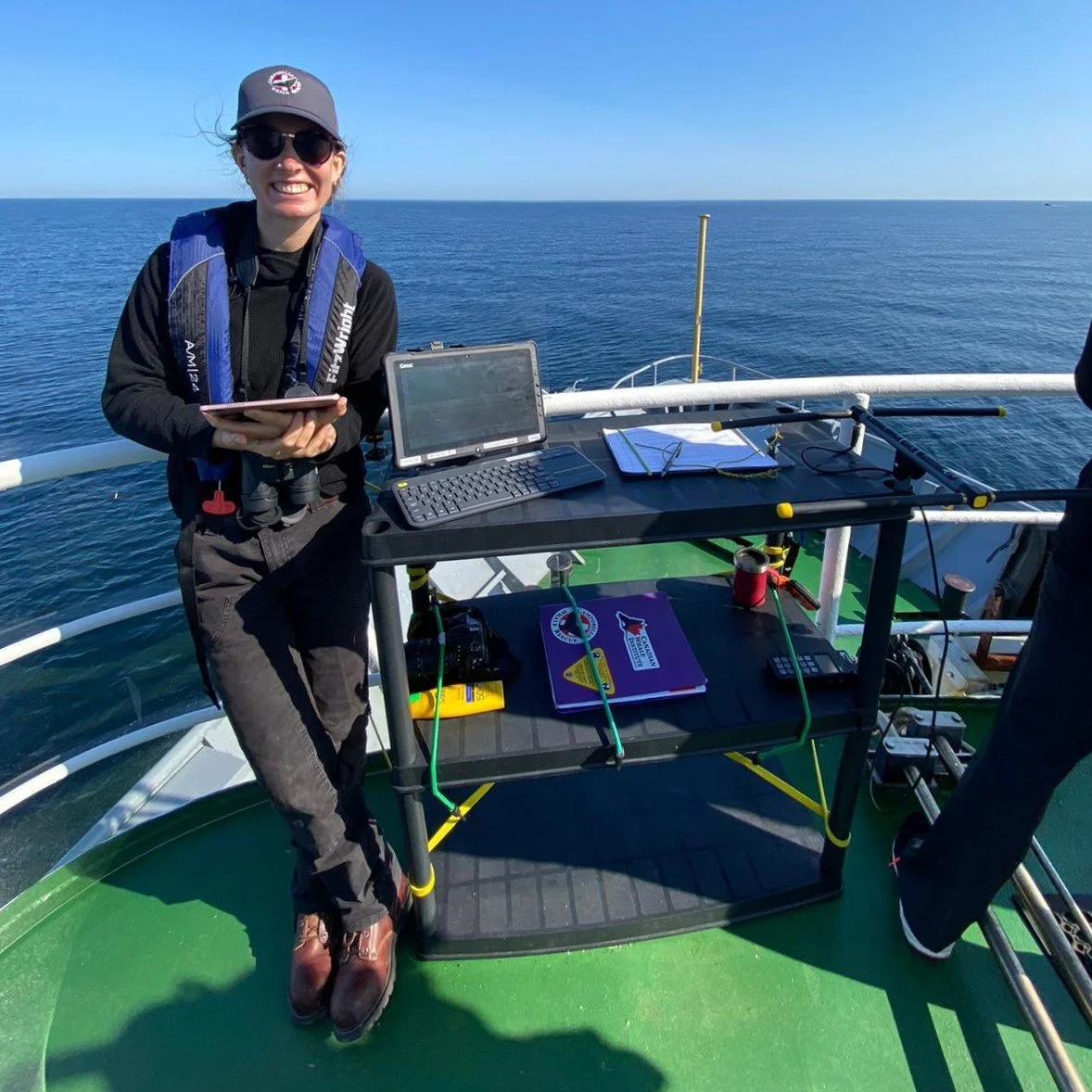

I am a robotics engineer at the Woods Hole Oceanographic Institution where I develop autonomous systems to perform remote ecosystem monitoring. I have a Masters in robotics engineering from Worcester Polytechnic Institute, a B.S. from Smith College in engineering and physics, and spent my early career at Formlabs developing SLA and SLS 3D printers. My professional interests include robotics, autonomous vehicles, data analysis and visualization, computer-aided design and rapid prototyping. It is my aim to apply these interests to marine ecological and climate issues.

My other passions include the outdoors, science fiction, ceramics, photography and (very) amateur piano playing.

You can find my resume here: link.

Contact

Email: lestanley48@gmail.com

Phone: (2O6) 9O2-7O5O

Github: github.com/LaurenStanley

LinkedIn: linkedin.com/in/lestanley48